When U.K.-based RS Components began diving deeper into its data to better serve customers a few years ago, little did it know that this transformation would make it a central player in the fight against COVID-19.

Under normal circumstances, RS Components offers a half-million different industrial products to customers in 30 countries, covering Europe and the Asia Pacific region. Since the coronavirus outbreak began, the world’s biggest distributor of electronics and maintenance products has broadened its scope, becoming a trusted partner to healthcare professionals and consumers, in addition to strengthening ties with its core B2B customers.

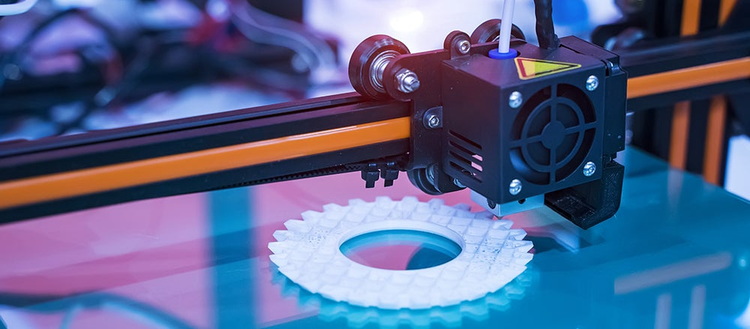

Take the case of 3D printing supplies. RS Components previously distributed 3D printers to customers around the world, but with doctors in the U.K. calling for respirators to treat COVID-19 patients and facing a three-week backlog, the company decided to use its own products to support efforts on the front line. Overnight, RS Components set up 3D printers in hospital car parks and began manufacturing essential respirator parts on-site for immediate use.

As Mike Bray, RS Components’ VP of innovation, said in a recent press announcement, the “collaborative effort among the 3D printing community will go some way to providing PPE [personal protection equipment] that is currently in such desperately short supply.”

A proactive, data-fuelled approach

For Andrew Morris, head of global insight at RS Components, the key to the company’s resilience has been its use of data insights, fuelled by Adobe Analytics. By looking at trends in countries that were affected by COVID-19 early, his insights team was able to predict how other populations would react and prepare their supply chains to meet local needs.

Led by Andrew Morris, the team supports its colleagues in marketing, sales, and supply chain with crucial data to help them make business-critical decisions. This relationship became more important than ever in December 2019, when RS Components noticed a shift in consumer behaviour on its Chinese website. Data from Adobe Analytics revealed a significant spike in demand for PPE product lines for the month, particularly in the city of Wuhan.

Once it became clear the virus was spreading, RS Components began to draw on data from countries where the COVID-19 infection had escalated, like China and Spain, to predict and proactively address needs in markets that would soon be fighting an escalation in the pandemic themselves. This allowed the company to ramp up awareness for its products at a local level and prepare its supply chains to meet demand.

For instance, after data from Italy revealed that the shift to remote working led to higher sales of headsets and office chairs, RS Components conducted in-depth data analyses to forecast demand in other countries and adapted its strategies to align with this trend. Its previous demand-planning software would not have been able to respond quickly enough to shifting customer needs, but with anomaly detection alerts in Adobe Analytics, powered by Adobe Sensei, RS Components was able to get ahead of these trends and be more proactive.

AI-powered alerts allow RS Components to forecast spikes in demand, like those seen in China and Italy. With better information, the company’s marketing, sales and supply chain teams can prepare ahead of time to deliver essential products where and when they are needed.

A catalyst to go digital

As with many B2B players, RS Components previously relied on direct mail and email campaigns to communicate with customers. The COVID-19 pandemic provided a compelling catalyst for change. Suddenly, RS Components’ marketing and sales teams had to shift their attention to digital channels to serve a remote audience with fast-changing needs.

RS Components’ marketing team now uses data insights to dial down the promotion of products that are in high demand, saving marketing costs. Using Adobe Campaign and Adobe Target, they can instead dial up awareness for related or alternate product lines that also add value for customers. Similarly, with insight into which industries are likely to return to work in each country they serve, RS Components’ supply chain team can proactively stock up on relevant products, such as hand sanitiser dispensers, mops, and cleaning supplies.

The transition to digital working also allows RS Components to make faster decisions, reducing the lead time for marketing campaigns from four weeks to just one. Such was the case for the company’s “By Your Side” campaign, which leveraged Adobe Audience Manager to create targeted audience segments for personalised campaigns.

For Morris, the real proof is in the customer relationships that RS Components has built during these challenging times. Not only has the company strengthened its B2B presence, it has also built tens of thousands of new relationships with consumers in need of PPE equipment and other supplies to stay healthy and productive during the pandemic.

At a time of uncertainty, RS Components has proved both resilient and indispensable, helping businesses around the world to prepare and continue operating through COVID-19. The company’s success has meant it will not need to accept financial support from the UK government to cover furloughed staff wages, opting instead to pay employees out of its own cash flow.

None of this would have been possible without data. Identifying and sharing valuable market intelligence across the organisation quickly has been instrumental in helping RS Components stay ahead and equip its customers in the fight against COVID-19, and it is a key reason why the company remains in such a strong position.