Decathlon successfully transforms its digital creation pipeline with Substance 3D

Decathlon is the world’s largest sporting goods retailer, with more than 1,700 stores in 59 countries. Offering an extensive selection of apparel and equipment across a multitude of sports, it successfully sells its products through a diverse portfolio of more than 50 distinct sub-brands, each operating for a different sports category and having its own unique product design pipeline. Around 850 engineers and 300 designers work on product design.

A few years ago, the company initiated its digital transformation journey by leveraging the power of the 3D design process in key aspects of their pipeline:

- Speed up the design process by having higher visual fidelity and consistency across the pipeline.

- Better informed decision-making on design would free up the designers’ time and allow for more creativity and product innovation.

- Reduce prototyping iterations and lower the company’s environmental footprint with fewer samples and physical prototypes.

To tackle the challenge of a fragmented design process, Decathlon first set out to create a centralized digital twin library while allowing each sub-brand to remain flexible in their workflow preferences. This allowed designers to get access to an extensive material library, digital replicas of the physical fabrics and materials that were commonly used within the company.

Learn more about how the Substance 3D toolset and Adobe ecosystem were used to successfully set in motion Decathlon’s digital transformation pipeline through a Q&A with Cyrille Ancely, Arik Schwarz and Swarnim Verma, the designers spearheading adoption of the company’s 3D transformation.

Cyrille Ancely: After graduating in transportation design from CREAPOLE ESDI, I started working as a freelance Industrial designer & 3D modeler for different car manufacturers. In 2019 Decathlon offered me the opportunity to join the company to define the Design of the Digital transformation process and its implementation, what we call internally, the “Digital Chain”.

Arik Schwarz: I’m a transportation designer and graduated from ISD in 2010. I have always greatly appreciated exploring new tools because they have often taught me how to adapt my workflow to improve my efficiency. I currently work for the brand Solognac, and I exclusively deal with the design of products for cold and wet weather (waterproof).

Swarnim Verma: I am a digital 3D designer, who graduated from ISD RUBIKA Valenciennes in 2022. I had the opportunity to do an internship with Adobe Substance 3D in 2019, during which I dived into the world of 3D materials. Right after graduating, I started working as a 3D designer in Decathlon, to further push ahead the use of 3D tools in CMF and apparel design.

Decathlon’s digital transformation

Cyrille: When we began working on the Digital Chain, we started with a state of play. Decathlon has a unique way of operating: each brand operates as an independent company within the group (69 brands at the end of 2021). In addition, there are 33 industrial processes such as Footwear, Textile, Optics, Electronics, etc., with specialized design offices serving these sports.

This structure makes it possible to identify the specific needs of each sport practice and to provide a specific response to them quickly. However, difficulties can arise when one wishes to accompany all the entities towards a unified digital transformation.

So, we went around the 9 design sites located in France to meet the different sports, processes, and collaborators. This allowed us to write a master plan to move to a group-wide deployment of the digitization process, including the implementation of the Substance 3D tools.

To raise awareness for the Digital Chain, we set up an internal event in February 2020 in which we highlighted various software tools and digital transformation practices . We also established conferences with both internal and external stakeholders (such as Adobe Substance 3D) to further gain momentum.

The COVID-19 pandemic highlighted the need to accelerate digital technologies. After the first lockdown we worked hard to define a master plan for the Digital Chain, which was put in place for an effective start in January 2021. Our policy is to support all our employees with digital design tools. As we have moved from paper/pencil to Photoshop/Illustrator, for us the next step was to move into a 3D environment.

The expected results were:

- A reduction of environmental impact (with a reduction in the number of physical prototypes in particular).

- Freeing up time for teammates to focus more on product excellence, eco-design, co-design and innovation.

We then defined several transverse improvement areas that serve the aforementioned objectives , the two main ones being:

- Digital product assets, which consist mainly of the creation of digital twins of all materials, accessories and assets, in the manner of an asset library of Substance 3D materials.

- A data management system for our products and assets.

The digital asset library

Cyrille: Our first objective was to help with internal transformation. Many collaborators are only beginning to understand how to work their product development with 3D tools; if we also asked them to understand how to create materials, scenes to present their products, etc., we knew we might lose a lot of them. Our goal was therefore to create plug and play assets in our various tools, whether for design or project reviews.

These same assets must be sufficiently qualitative for CGI experts to use in their workflow. We decided to start work on flexible assets, materials found in the device, luggage storage, or shoe shafts. We work with a partner who digitizes each material with a Vizoo-type scanner, handles the tilling, and sends back the physical samples as well as the maps from the scan.

Our team then takes care of the post-processing. In about 70% of the cases, the maps received are sufficient to create qualitative digital materials in Sampler; we perform slight reprocessing as the creation of masks allow us to edit the colors separately in the case of multicolor materia ls. In other cases, the post-treatment may be heavier and requires either a mix scan based/procedural treatment, or a full procedural recreation with Substance 3D Designer.

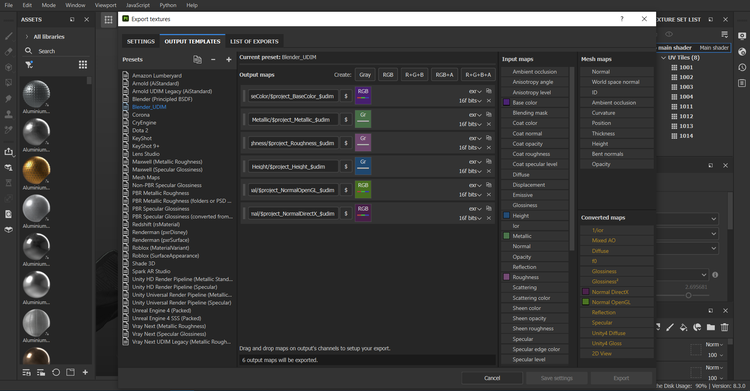

In either case we export an SBSAR and maps that we import into Keyshot in order to create a specific material for this tool.

We keep the number of parameters exposed in the SBSAR to a minimum, to prevent designers from creating a material that does not exist in our offering. For example, only the color change parameters are exposed now. In the case of CMF, we have a different approach.

The processing time is very variable, it can range from a few minutes to several days depending on the complexity of the material.

To date, the database has about 3,765 assets.

Advantages of a digital twin library

Cyrille: The main advantage is having a single, defined location where our designers can find the assets they need, rather than having to search through multiple shared folders of different users.

What we did not anticipate was the constant updating required to manage a digital twin. So, we decided to hire a Tech Artist, which allows us to implement tailor-made tools that facilitate the management and creation of our assets. In fact, the management of asset data has also become one of the essential points of this lever.

Apparel workflow

Arik: I retrieve the textures available in Substance format and integrate them into CLO3D. This allows me to work on the fabric’s drape to get a realistic visualization. Otherwise, during the exploration phase, my colleagues in the Digital Chain prepare customizable Substance 3D materials that I can then modify directly in CLO3D. This provides a qualitative visualization that is easy to share with the rest of the team. Substance 3D materials are giving life to my 3D models. The incredible visual and texturing features of Substance enhance my creative work and reduce my workflow steps.

For me, Substance is an indispensable tool to achieve an impeccable quality of textile products. It is bridging the gap between a creative 3D file and production. Before, I created visuals in Photoshop and Illustrator that I later imported into CLO3D. This allowed me to push some ideas, but the format was much less flexible and photorealistic. We can talk about a big revolution in the apparel design workflow which is putting textile creation at the same level as product development.

CMF

Swarnim: Using Substance 3D Designer allows component designers to visualize their ideas for different motifs and patterns, finishes (matte, shiny etc.) and colors on a material:

- To make and try out variations and view the results in 3D in real time. We can very quickly generate up to 10 times the number of iterations of patterns that we could on Photoshop/Illustrator very quickly because of procedural nodes, all in 3D.

- To create more precise visuals which express the modifications component designers need in an existing material in order to make it easier for them to discuss the development with fabric suppliers.

Coupled with a 3D software for apparel and fashion design like CLO 3D, Substance 3D Designer is even more powerful because it allows component designers to visualize many different iterations more rapidly on digital prototypes of actual clothes, thereby giving them the possibility to produce several digital prototypes and being more certain of their choices before making the physical prototypes.

Close up renders in Substance 3D Stager

Export from Painter and scene setup in Blender

Final render in Blender

Ski suit modeling: Audrey Mathelet & Maxime Devauchelle.

CMF, texturing, and rendering: Swarnim Verma & Timothée Ryckeghem

Cyrille: We are currently working on the impact that these tools will have on CMF and how the design of a textile material becomes a 3D design workflow, in the same way as those mentioned previously (Apparel, Footwear, etc.).

We estimate that we can multiply between 10 and 60 times the number of iterations we produce over the same period compared to our old way of drawing a textile material.

Global takeaways

Cyrille: The integration of Substance 3D in the creation process and industrialization process has allowed us to gain more control, to increase the quality of our products and therefore the satisfaction of customers/users.

We identified three improvements:

- Reduced product development time: -33% on Apparel and Bags

- Reduction in the number of prototypes: -33% on footwear

- Increased number of CMF iterations: between 60 times more

The future of 3D at Decathlon

Cyrille: We work globally on the management of change within the different teams at Decathlon by:

- Supporting our CMF designers towards the use of Sampler and Designer

- Overall making the Substance 3D toolset available for 3D experts at Decathlon.

In the journey to digitize its design processes, Decathlon faced a range of challenges, from a fragmented organizational structure to workflow and visual inconsistencies to environmental concerns. By integrating Substance 3D as a core component of their Digital Chain strategy, they were able to streamline asset management, increase fidelity and consistency across their design process, and have more time for creative iteration without increasing the time it takes to bring products and updates to market.

Thank you to the Decathlon team for allowing us to take a peek into their design process and the benefits of their Digital Chain approach.

Adobe Substance 3D is a comprehensive and integrated toolset for creating, managing, and applying photorealistic materials throughout the product design process. Learn more about how Adobe Substance 3D can help you transform your approach.