How Tapestry is scaling fashion design with digital twins and Substance 3D

Digital twins, high-fidelity digital representations of physical products, are reshaping how the fashion industry designs, develops, and markets everything from bags to footwear. As brands strive for more speed, creative flexibility, and sustainability, 3D workflows have emerged as a critical driver of innovation across the entire product lifecycle. One company leading this shift is Tapestry, the house of iconic brands Coach and Kate Spade.

At the heart of their transformation is the Digital Product Creation (DPC) team, based in New York City. By integrating Adobe Substance 3D into their pipeline, the team is scaling digital twin production to accelerate design decisions, reduce physical prototyping, and unlock new possibilities from design to merchandising and marketing.

Tabby Shoulder Bag 26: physical product (left) and its digital twin (right).

Inside the DPC team

Carmen Ortiz, manager, Digital Product Creation: We advocate for the use of digital product creation technologies across all our brands and product categories. 3D bridges the communication gap between product developers, designers, manufacturers, and merchandisers by providing early visibility when co-creating products across the globe.

The benefits of DPC and 3D workflows are speed, agility, accuracy, cost effectiveness, and sustainability. Our team has grown to support all our product categories , including handbags, small leather goods, ready-to-wear, hardware, footwear, special accessories, and jewelry.

Brandon Keeney, senior manager, Digital Product Creation: We research and implement new tools both internally and externally. Although we sit under product development, because our assets are design-approved, we have been receiving many requests from multiple parts of the business.

Our projects involve co-creating with designers, virtual sampling, and collaboration with sales, merchandising, and product development for innovation, visualization, and decision making. We also support our Global Visual Experience team for things like pop-ups and social, as well as content creation with our internal photo studio for e-commerce.

The need for digital twins

Ortiz: Before implementing 3D into the pipeline, designers made decisions based off 2D vector CADs. I started using Substance 3D back when I was on the Design Technology team, mainly for providing assets for internal and customer-facing virtual showrooms.

Since 2021, we have merged with the 3D team and are now Digital Product Creation. With this joining of forces, we’ve been able to integrate and push the 3D process even further. This also means that expectations have been heightened: the better our renders become, the more they’re analyzed, which consistently pushes us to innovate.

With the use of Substance 3D Stager, we’re able to achieve high-quality renders fast. We’ve been able to work with our internal photo studio to get the lighting and camera angles looking identical to physical product shots and standardize the rendering process.

Keeney: One project in particular highlights how quickly digital twins can accelerate development. One example is of a project that was stuck at the supplier level for two years – the DPC team was able to take it from concept to design approval within two weeks. We received the design card, modelled it, and visualized it in Substance 3D Painter. We then passed the digital twin to 3D printing, creating a high-fidelity version of the prototype, and Product Development went through and commercialized it.

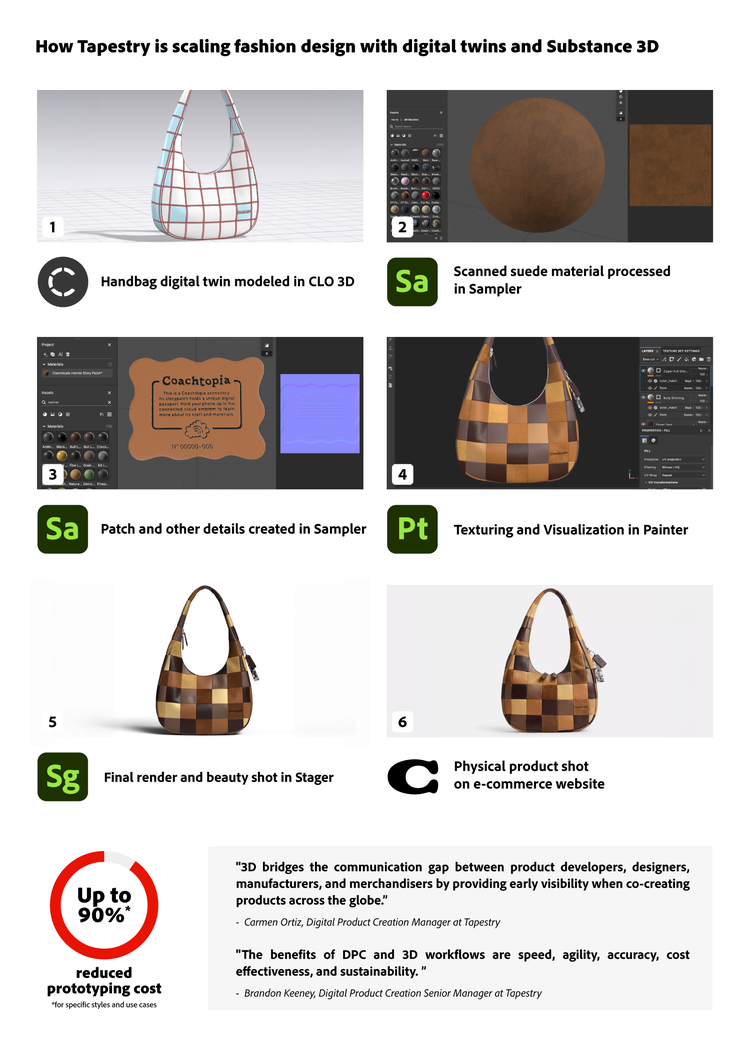

The DPC workflow with Substance 3D

Keeney: We leverage a “create once, use many” mindset. Development begins with a concept sketch or a design card. From there, we start the 3D modelling process, using tools like Rhino, CLO 3D, or ZBrush. Once all the design details are approved, I send the 3D model to Carmen to start the visualization process. This is where Substance 3D enters the picture as a central piece of the team’s pipeline.

Ortiz: While Brandon is prepping the 3D model, I utilize Substance 3D Designer, Substance 3D Sampler, and our in-house material scanner to develop materials. Then we use Substance 3D Painter for texturing and visualization. I also like to include Sampler in this part of the process because we create a lot of embroidered patches. And then finally, once we finish visualization, we use Substance 3D Stager for rendering.

And now we have an asset that can be utilized all the way down the pipeline.

Ortiz: This workflow helps us create a consistent pipeline of assets. It’s also super streamlined within the Adobe ecosystem. Coming from a traditional design background, I personally love that Photoshop and Illustrator are also very well integrated.

These integrations also help solve unexpected design challenges quickly and efficiently. For example, we hit a roadblock where a bag needed a specific hardware piece. I was able to take it in Illustrator and use the Illustrator to 3D export, and I created a rivet in a matter of seconds.

Ortiz: Here is an example of the Soft Empire Carryall 48. This bag was (Re)Loved, which means it’s made of previously worn leather. In my material layers, I always start with my base, then build off from there. I can use all the amazing Substance 3D Painter brushes to layer on this worn look. Once I got it right, I moved to Stager for rendering, where I can add my New York City bag charms.

Saving on prototypes, costs, and samples

Ortiz: 3D is great for fast prototyping. This helps design teams make decisions and changes a lot faster than waiting for a sample to arrive, which then reduces turnaround times.

Ortiz: The Jelly Tabby is a perfect case study in both time and cost savings. This sequence shows our Jelly Tabby bag going from a 3D model all the way to commercialization. Thanks to 3D visualization and 3D printing, we got to the final product faster and in a more cost-efficient way.

Keeney: Previously, developing a mold for this type of bag involved significant costs per iteration at the supplier level. Now, by integrating our 3D pipeline, we have achieved a transformative reduction in prototyping expenses, bringing costs down to a fraction of their original level. This dramatic improvement in ROI became a pivotal factor in driving adoption, making previously cost-prohibitive innovative development accessible and achievable.

Ortiz: Since we're able to create such lifelike digital samples in 3D, it helps to reduce the number of physical samples. These meet our sustainability efforts, especially for Coach’s sub-brand Coachtopia, which uses upcycled and recycled materials to work towards their mission of circularity in fashion.

One asset, multiple outputs

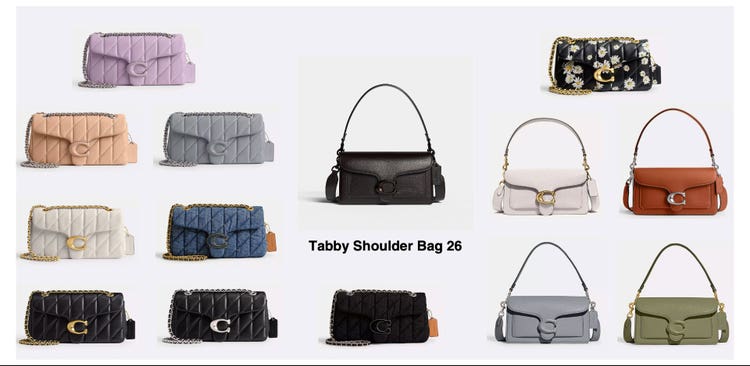

Keeney: The need for digital assets is skyrocketing, and our challenge today is scaling. This is one of our hero styles at Coach, the Quilted Tabby 26. In the middle is our 3D model of the Tabby 26. But we need to create all of these variations as digital assets. We leverage Substance 3D Painter to achieve this.

Ortiz: Since it’s super intuitive, coming from a traditional accessories design background, we believe that all our designers should be using Substance 3D, something we are currently working on.

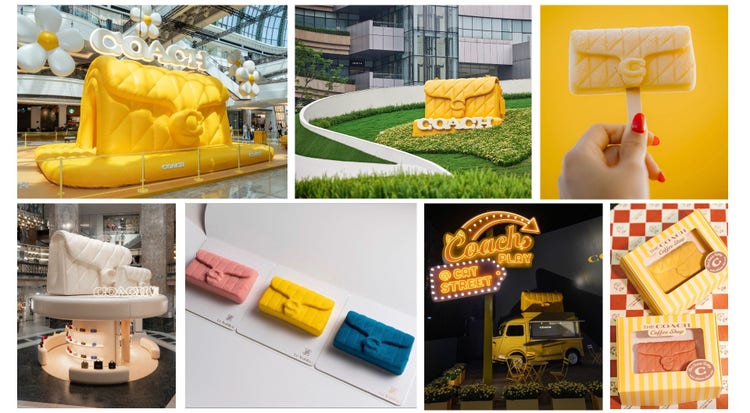

Keeney: The power of the “create once, use many” mindset comes to life in marketing and retail activations. Our 3D Quilted Tabby model was used in many different experiences, as you can see below. All the way from a cute cake mold to a popsicle, a bounce house, and even on top of a food truck. These projects just really show how powerful our assets are and how just about anything imagined can be created from just one 3D model.

Tapestry’s Digital Product Creation team is proving that 3D workflows and digital twins are transforming fashion design today. By creating high-fidelity digital twins of products, brands can streamline prototyping, reduce waste, and enable creative teams to reuse and repurpose assets across design, merchandising, marketing, and retail. With Adobe Substance 3D at the core of their pipeline, Tapestry is scaling digital twin production to drive speed, consistency, and sustainability across the entire product lifecycle, showing what’s possible when virtual and physical design work seamlessly together.

Learn more about how Substance 3D can support your creative process.